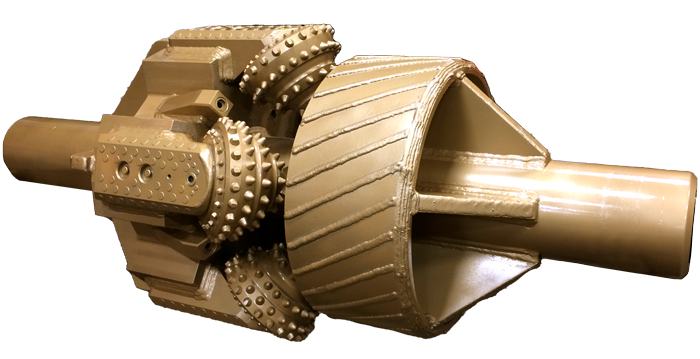

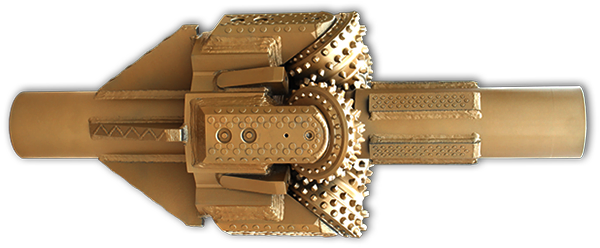

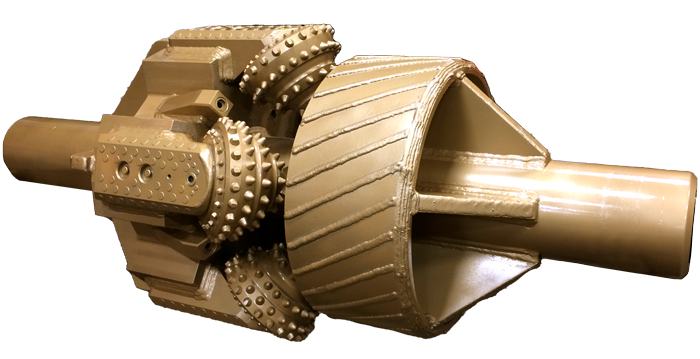

Precision-machined solid body welded to a Shaft

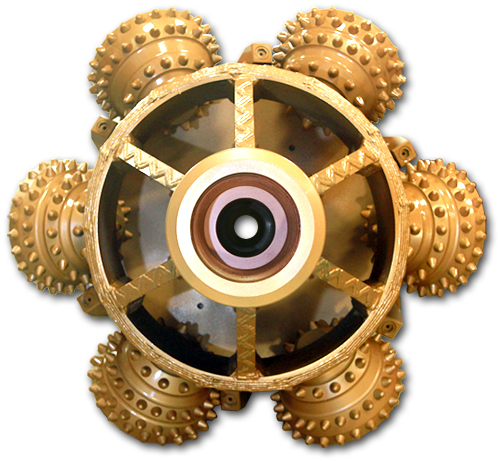

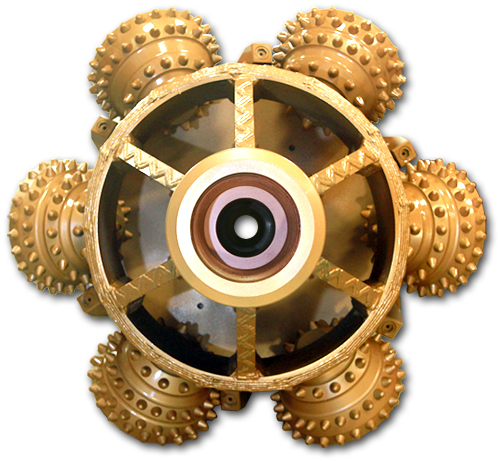

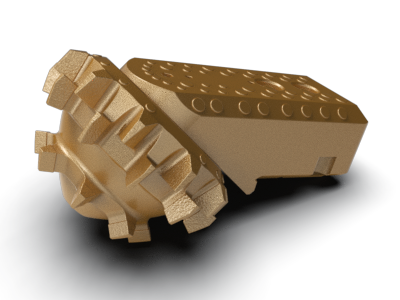

Patented pocket arm design

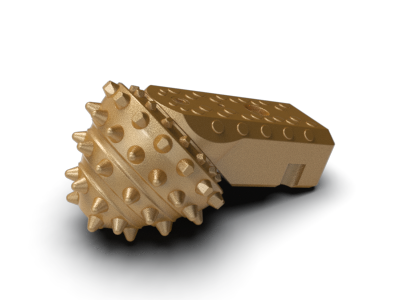

Replaceable Arm & Cone Assemblies

Sealed roller journal bearing technology

Largest cross section seal in the industry

Provide greater cutting action with larger carbide inserts

Eliminates the need for extra reaming passes with larger cones

Extends the bearing and seal life with reduced cone revolutions

Allows increased load capacities due to larger bearings